Originally seven Holt-Allen HA123 drainage hole fittings were supplied with the kit. 5 for the drainage holes into the tanks, two for the drainage holes in the stowage bulkhead. The Bell Woodworking instructions state

These nylon fittings are screwed into the drainage holes in the tanks. To ensure a watertight fit, they should be glued and screwed into position, with 1/2" X 6 (guage) screws.

By 1969 these fittings were supplied with semi-transparent plastic plugs/caps. These are much better than corks or rubber bungs as they are hard to dislodge by accident with your foot. Sadly these are no longer available, but there are alternative, slightly inferior, plugs available.

I, like a lot of racers, don't close the drainage holes in the stowage bulkhead. Generally water finds it's way into the cuddies via the halyards, so it's best to just let it drain out into the cockpit naturally. I've removed the fittings to save a small amount of weight and minimise pooling inside the cuddies.

Quite a bit of modification of the drainage hole fitting is needed to ensure all the water in a tank drains out though the drainage hole. If this is not done, a small amount of water may remain in the tank and this can lead to water ingress into the plywood and, in the long term, rot.

The shaft on the standard Holt-Allen 123 is about 15mm long, much thicker than the (typically 5mm thick) bulkheads and side tank side panels. So I cut my fittings down so they are flush with the plywood surface inside of the buoyancy tank. I also don't bother to screw these on, so I cut the flange to remove the holes for the screws. I make sure the hole is as low as possible, and that the fittings are a snug fit through the plywood, then carefully varnish the bung holes, and then glue the fitting in place with epoxy.

I also put some low density filler (epoxy resin + West 410 microlight filler) inside the tank under the fitting to ensure any water cannot pool and will flow out of the hole.

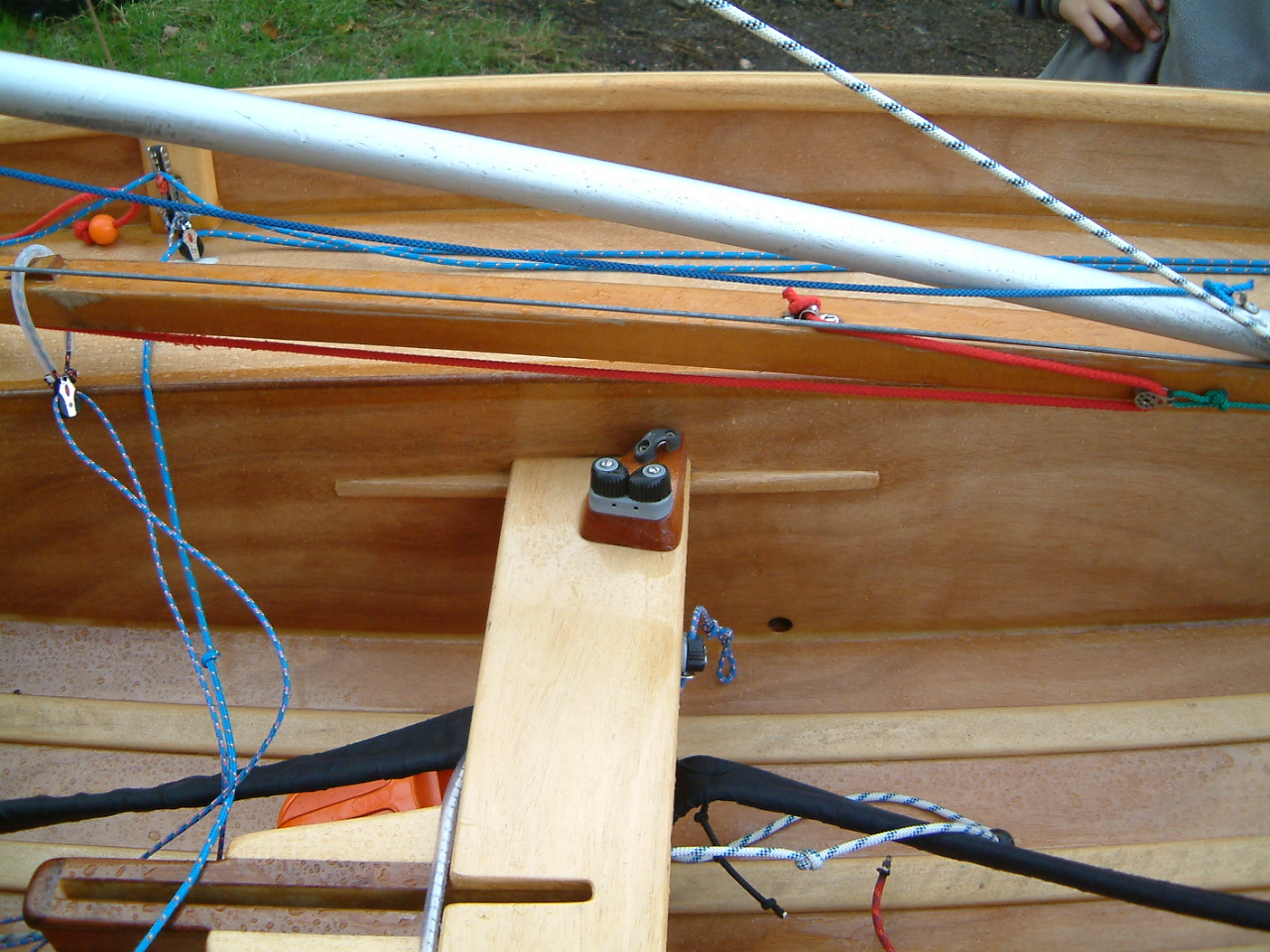

Or, you can avoid all the complication, and just have a drainage hole and no fitting, as in the photo above.

On this boat, when sailing, the hole was closed with a rubber calf teat.